Julius Caesar claimed, “Alea Iacta est.” Translated, this means that a course of motion has actually been finalized, which happens to be fitting for the reason that an index of hugely skilled pharmaceutical/biopharmaceutical organizations and suppliers of kit and parts had been assembled.

In advance of discussing the cleanroom elements of design or perhaps the Heating, Air flow and Air Issue (HVAC), it is actually important to 1st realize the movement of staff, sterilized elements and sterile product in acquiring the cleanroom layout and operation. The movement requirements may perhaps differ with each sterile drug developed.

This type of progress will minimize affected person manipulation and boost client protection, along with supply their innovators with differentiation And maybe mental property.

The Automobile-Pinch fifty is an automated timed flow volumetric filling device effective at filling drinking water thin liquids to light-weight oils and creams at speeds of around one hundred containers per minute.

Plastic bottles are versatile and sturdy, generating them handy in an array of industries. Our machines can handle plastic bottle filling, from smaller containers to big jugs.

The Accutek Automated AccuCounter is surely an computerized pill counting machine ideal for the electronic capsule counting and filling of difficult gelatin capsules, smooth gels, tablets, round supplements, hard candies and a variety of other reliable solutions.

The purpose is to deliver a exact level of product to The buyer in a sexy bottle that promotes your featuring above the Competitors.

What this means is working with sterile raw supplies, sustaining sterile environments, and subsequent strict strategies to forestall contamination at just about every phase get more info from the manufacturing process.

There may be also the notion situation for aseptic fill/complete, which is another reason for the numerous safeguards which i will explore shortly, considering the fact that micro contamination is not conveniently obvious.

The gowning and aseptic methods are the same as a barrier fill/end operation. The advantages which have been documented are minimized money expense, more rapidly validations and operational commence-up, reduction in lot-to-lot transform close to time. RABS operations have documented contamination Management about a conventional barrier fill/end procedure.

Filling lines and critical procedures really should be bodily separated from operators. Devices within isolators or RABS may help to drastically Manage contamination.

Assuming which the manufacturing course of action style Place continues to be thoroughly produced and CQAs and DOEs are already verified, technological know-how transfer, together with scale-up, ought to go smoothly. As with most standard API-manufacturing operations, procedure layout and controls ensure a state of control.

Any moisture will pace the decomposition of substances in pharmaceutical or nutraceutical strong dose solutions. NJM is able to integrate a complete packaging line with the right desiccant dispenser on your challenge.

In addition, The mixing of Innovative analytics and equipment Finding out algorithms can help predict and forestall problems right before they take place, optimizing click here the manufacturing system and minimizing the chance of products defects.

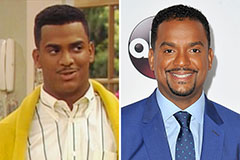

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!